Modern power systems rely on substations to step up or step down voltages, distribute electricity efficiently, and ensure grid stability. Among the widely used types, Gas Insulated Substations (GIS) and Air Insulated Substations (AIS) stand out. While both serve the same fundamental function, their design, construction, and operational characteristics differ significantly.

In this article, let’s explore the key differences between GIS and AIS to help engineers, project managers, and decision-makers choose the right technology for their projects.

1. Basic Concept

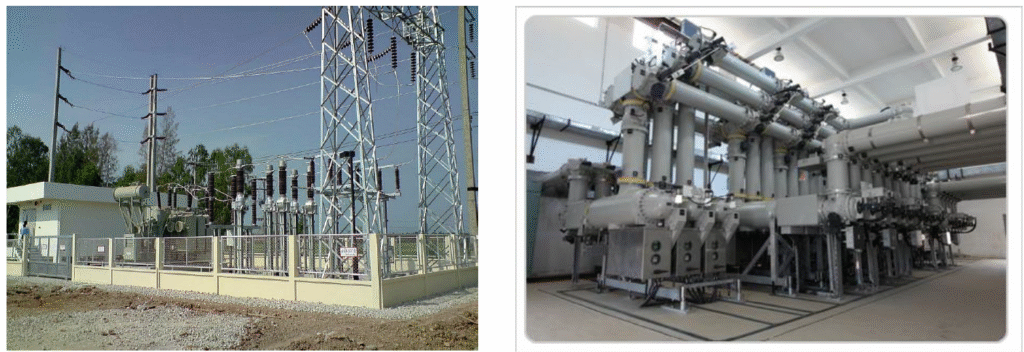

- AIS (Air Insulated Substation)

Uses air as the primary insulating medium. Conductors and equipment are installed in open yards, with air providing insulation between live parts and ground. - GIS (Gas Insulated Substation)

Uses SF₆ (sulfur hexafluoride) gas inside sealed chambers for insulation and arc quenching. Components are enclosed in metal-clad modules, resulting in a compact footprint.

2. Space Requirements

- AIS: Requires large open areas due to minimum air clearance between phases and to ground. Ideal for rural or semi-urban installations where land is available.

- GIS: Very compact — up to 70% smaller footprint than AIS. Perfect for urban centers, industrial zones, or underground installations.

3. Installation and Construction Time

- AIS: Simpler design; faster to erect in open yards but weather conditions can delay construction.

- GIS: Prefabricated modules allow quicker assembly once delivered, but manufacturing and pre-testing may take longer.

4. Maintenance

- AIS: Easier to inspect and repair since the equipment is exposed and accessible. However, outdoor exposure leads to higher maintenance due to weather effects (dust, humidity, corrosion).

- GIS: Minimal maintenance; sealed modules are protected from environmental factors. Specialized training and equipment are needed for servicing.

5. Reliability and Safety

- AIS: More prone to faults from external factors (animals, lightning, pollution).

- GIS: Higher reliability; enclosed design reduces risk of faults and improves safety for personnel.

6. Cost Factors

- AIS: Lower initial cost (equipment and installation) but higher land cost in urban areas and recurring maintenance expenses.

- GIS: Higher upfront cost due to SF₆ gas and compact design but reduced land cost and long-term reliability often justify the investment.

7. Environmental Impact

- AIS: No greenhouse gas concerns but requires larger land clearing.

- GIS: SF₆ gas is a potent greenhouse gas — strict handling, monitoring, and recycling measures are mandatory.

8. Applications

- AIS: Preferred for rural substations, large power plants, and transmission nodes where space is abundant.

- GIS: Common in urban substations, industrial facilities, offshore platforms, and high-voltage installations (110 kV and above).

Comparison Table: GIS vs AIS

| Feature | GIS Substation | AIS Substation |

| Insulation Medium | SF₆ Gas | Air |

| Space Requirement | Compact (up to 70% less) | Large open area |

| Maintenance | Low, specialized | High, easier access |

| Reliability | Very high | Moderate |

| Cost | High initial, low land | Low initial, high land |

| Environmental | SF₆ handling required | Land use impact |

Conclusion

Both GIS and AIS substations have their unique advantages. AIS is cost-effective and suitable for spacious locations, while GIS is compact, reliable, and ideal for urban or space‑restricted projects. The right choice depends on project requirements, available land, voltage levels, budget, and environmental considerations.

By understanding these key differences, engineers and planners can make informed decisions that align with both technical and economic goals.

🔗 Related Blogs

- ⚡ GIS Substations: Key Advantages & Applications

- ⚡ When and Why to Choose GIS Substations for Power Projects